Jeep Underglow

04 Wednesday May 2016

Posted in Uncategorized

04 Wednesday May 2016

Posted in Uncategorized

07 Monday Mar 2016

Posted in Raspberry Pi

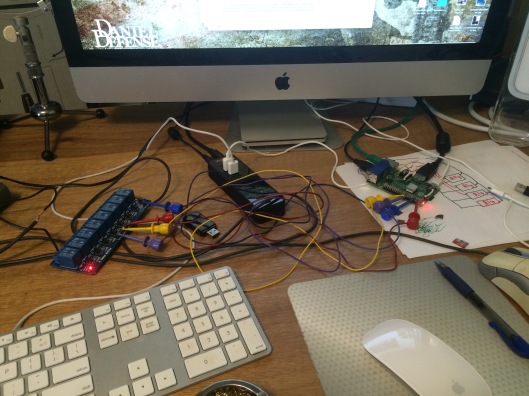

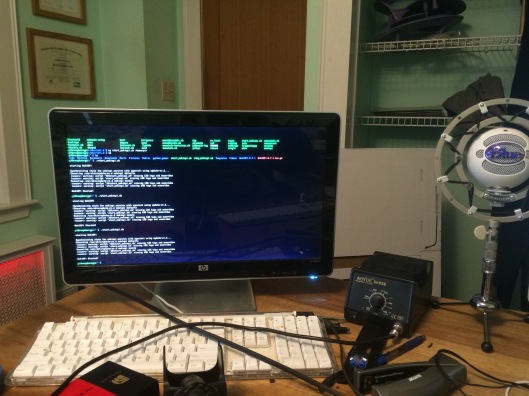

Continuing on my quest to control everything in my house from a phone or computer, over the last few days I’ve been working on controlling relays over my home network with a raspberry pi. I stumbled upon a really great framework for controlling the pi’s GPIO pins through the web called WebIOPi. It makes it very easy to serve a web app off the pi to control or see input from the pins, as well as providing an easy way to do the same in locally run python scripts.

First I set up a fresh install of raspbian, then just followed the installation instructions provided on the WebIOPi website. I used a model 2 pi, so I also had to use this patch to change the memory mapping.

It’s always fun to really be able to see your project work, so instead of being satisfied hearing the relay click on and off, I connected it to some LED strips I stuck in my radiators.

The wiring was very clean

I also wrote some bash scripts to make it easier to start and stop the whole program, as well as making it automatically initialize at startup.

In the end, I can now turn my radiators red from my phone. Not the most useful project, but it looks pretty cool and I gained a lot of experience in stuff I had never done before. Next step is to build a nicer controller app more specific to my room, and put more things under the pi’s control.

04 Friday Sep 2015

Posted in Raspberry Pi

Tags

I haven’t done much with Raspberry Pi before, and after an underwhelming attempt at controlling stuff over the internet with an Arduino ethernet shield, I decided to do a project to force myself to learn more about using a Pi. The project I went with was setting up an Owncloud Server. Owncloud is basically a free dropbox clone that you can run on your own server. This means that not only do you know exactly where your data is stored, and what security measures are taken to protect it, but you can attach external storage to give yourself terabytes of cloud storage with no huge monthly fee. There are desktop clients for windows, linux, and osx, as well as clients for ios and android. Overall it’s some pretty cool software, and really easy to set up with some basic bash knowledge. I got help from raspberrypi.org as well as projpi.com. I used a RasPi B+, but I would recommend a 2B, because I was constantly maxing out the cpu even at the turbo overclock preset.

18 Tuesday Aug 2015

Posted in Uncategorized

I needed timed control over a high powered led, so in my typical overkill fashion instead of just using a simple timer switch, I decided to use an arduino. The overall system consists of 3 parts. A box with the arduino and LED driver, a lightswitch, and an LED mounted on an outrageously large heatsink.

The sketch checks if the switch is on, and while it is, keeps the light on for an hour. After that hour, if the switch hasn’t been switched off (that starts the process over) it dims the light for 5 seconds, then shuts it off. I gave it a 5 second buffer so if one were still in the room they would have time to get back to the switch before the room plunged into darkness.

The one major quirk was that the LED driver I was using needs the opposite of what you would think to turn the led on and off. 5 volts to turn the led off, and 0 volts for fully on. If you look at the code, since I figured that would not be the case for most lights, I added a variable you can change to either have 5 volts be on or off for the led/light controller.

The other major nuisance was that the LED got really hot, really fast. I didn’t have much time, so I just threw the smallest heatsink I had that could handle the heat on the led.

09 Tuesday Dec 2014

Posted in Uncategorized

Tags

I recently got a good deal on 2 nerf longstrike cs-6s, so I am going to try to make one select-fire. In the mean time however, I found the adjustable stock pretty inadequate. It is either all the way out:

or all the way in:

When it is out, it has a good length of pull, but is longer than it needs to be. When it is in, you can’t get you hand on the grip very comfortably. To over come this, I dismantled the blaster, and found that what locks the stock into those two positions is just a hole drilled into the back of the blaster that a little tab pops into. All you need to do to fix the problem is drill another hole of the same diameter in between the existing ones:

you then have a shorter length of pull but enough room for your trigger hand:

01 Monday Jul 2013

Posted in Uncategorized

Tags

I decided I needed a better trap for my nerf gun, so i built this. Also, to test it out i smashed through a can. The backstop works perfectly!

18 Saturday May 2013

Posted in Uncategorized

Tags

Here is a video of the nerf gun in action

18 Saturday May 2013

Posted in Uncategorized

Tags

This is a project I have actually been working on for a while now, but since I finally started this blog I figured I should start posting about it. The original goal was to make the highest powered and most accurate nerf gun that I could. I realized that because I was using nerf darts, the accuracy part was out the window, so i just went with highest power. In its current configuration, with the compressor I have access to, it can shoot a dart through 10 layers of corrugated cardboard and a heavy duty sheet. This is at 150 psi. the valves I am using are rated up to 600 psi, and most of the tubing is rated to around 3,500 psi. I am hoping to soon get a paintball co2 tank and regulator so I can find out the guns full potential. My new goal is to make a nerf dart break the sound barrier.